WHAT IS IK STANDARD EN/IEC 62262?

IK Standard EN/IEC 62262 defines the impact resistance of electrical equipment. It measures how well the equipment can withstand mechanical shocks from external forces. This rating system helps determine the durability of devices when exposed to specific levels of physical stress, ensuring they can handle various conditions. The IK rating is crucial for assessing the toughness and reliability of electrical devices (Some references are Industrial Monitors,EV Chargers, Outdoor Monitors) in different environments, protecting them from damage caused by accidental impacts.

EN 62262 IK code table

| IK code | IK00 | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK10 | IK11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact energy (Joule) | * | 0.14 | 0.20 | 0.35 | 0.50 | 0.70 | 1.00 | 2.00 | 5.00 | 10.00 | 20.00 | 50.00 |

HOW TO Perform AN IK TEST

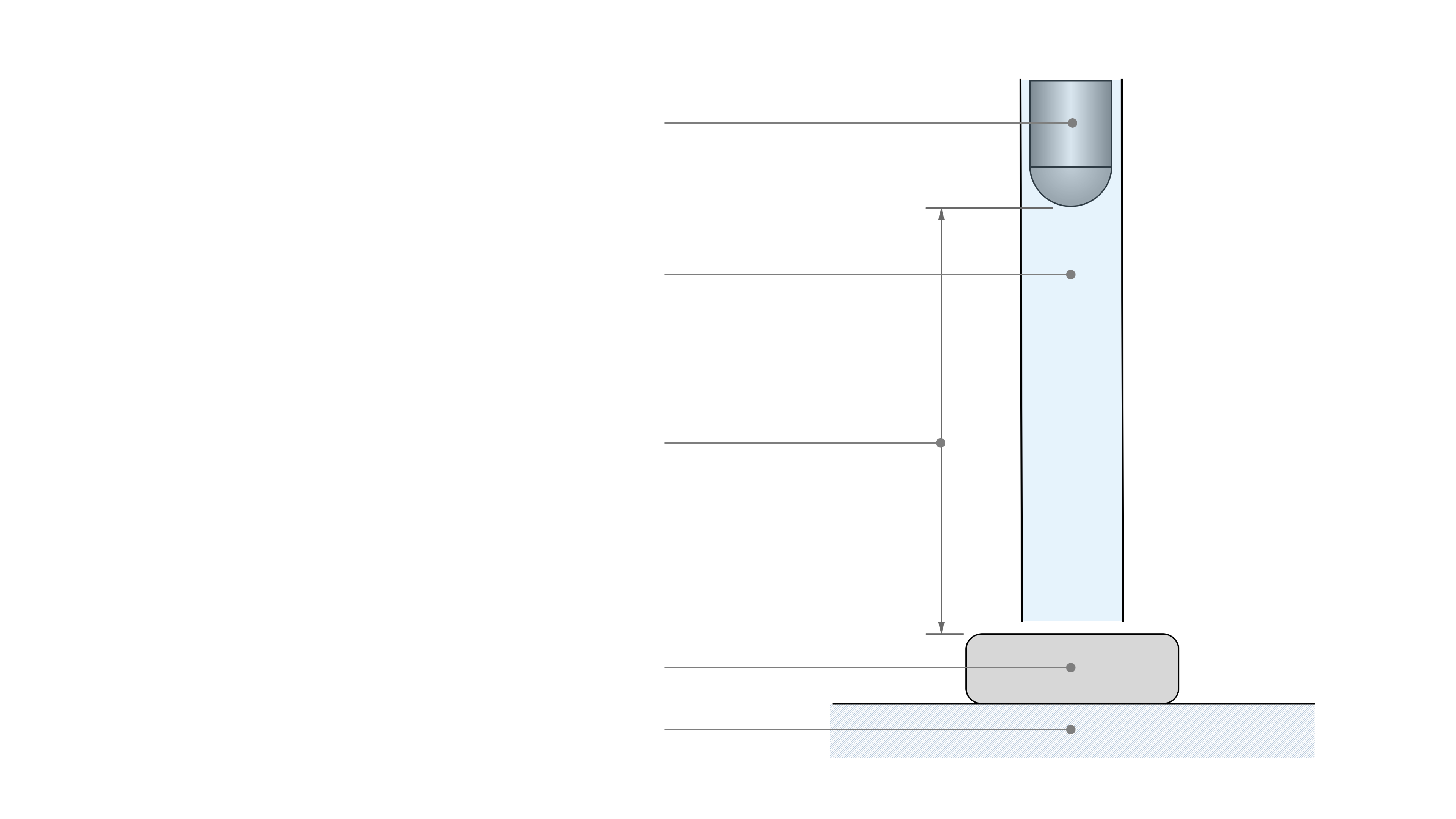

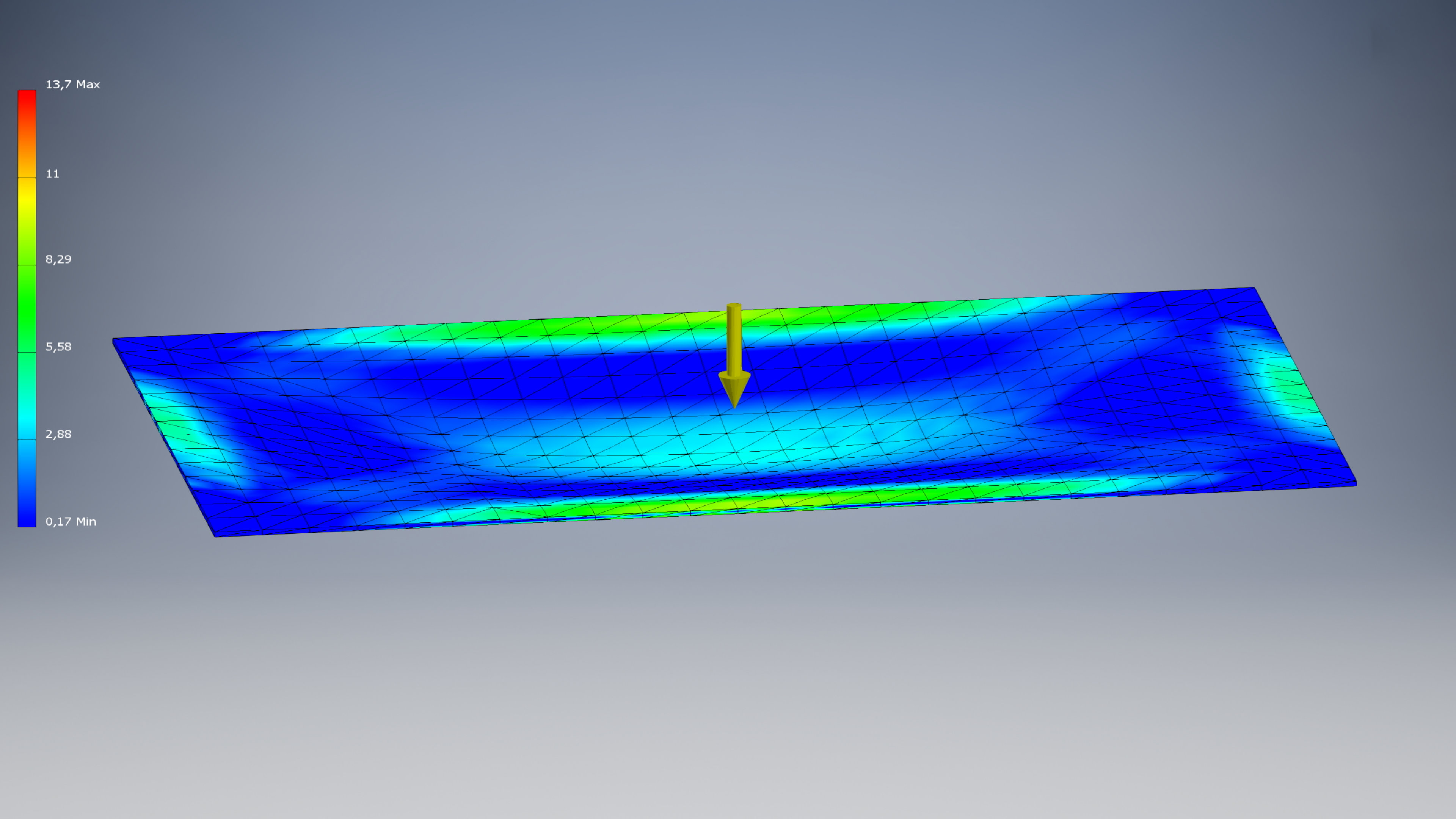

To conduct an IK test, an impact element—typically a pendulum or a free-falling object—is dropped onto the material or surface being tested. The impact element has a precisely defined weight and shape, tailored to simulate specific conditions that the material might encounter in real-world situations. The height from which the element is dropped is carefully selected to control the amount of energy delivered upon impact. This energy level is crucial because it directly influences the force exerted on the material.

Impact Force Calculator

IMPORTANT

The EN 62262 standard outlines only the impact energy levels. The procedures and conditions for testing are specified in the EN 60068-2-75 standard. The table below is NOT part of EN 62262 but is instead included in EN/IEC 60068-2-75. Please refer to EN 60068-2-75 for the detailed test procedures and conditions.

EN 60068-2-75 Dimensions table of impact elements

| IK code | IK00 | IK01 | IK02 | IK03 | IK04 | IK05 | IK06 | IK07 | IK08 | IK09 | IK10 | IK11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact energy (Joule) | * | 0.14 | 0.20 | 0.35 | 0.50 | 0.70 | 1.00 | 2.00 | 5.00 | 10.00 | 20.00 | 50.00 |

| Drop Heigth (mm) | * | 56 | 80 | 140 | 200 | 280 | 400 | 400 | 300 | 200 | 400 | 500 |

| Mass (kg) | * | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.50 | 1.70 | 5.00 | 5.00 | 10.00 |

| Material | * | P1 | P1 | P1 | P1 | P1 | P1 | S2 | S2 | S2 | S2 | S2 |

| R (mm) | * | 10 | 10 | 10 | 10 | 10 | 10 | 25 | 25 | 50 | 50 | 50 |

| D (mm) | * | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 35 | 60 | 80 | 100 | 125 |

| f (mm) | * | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 | 6.2 | 7 | 10 | 20 | 20 | 25 |

| r (mm) | * | – | – | – | – | – | – | – | 6 | – | 10 | 17 |

| l (mm) | * | Must be adapted to the appropriate mass | ||||||||||

| Swing hammer | * | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Spring hammer | * | Yes | Yes | Yes | Yes | Yes | Yes | No | No | No | No | No |

| Free fall hammer | * | No | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

* not protected according to the standard

1. Polyamide 85 ≤ HRR ≤100 Rockwell hardness according to ISO 2039/2

2. Steel Fe 490-2 acccording to ISO 1052, Rockwell hardness HRE 80...85 according to ISO 6508

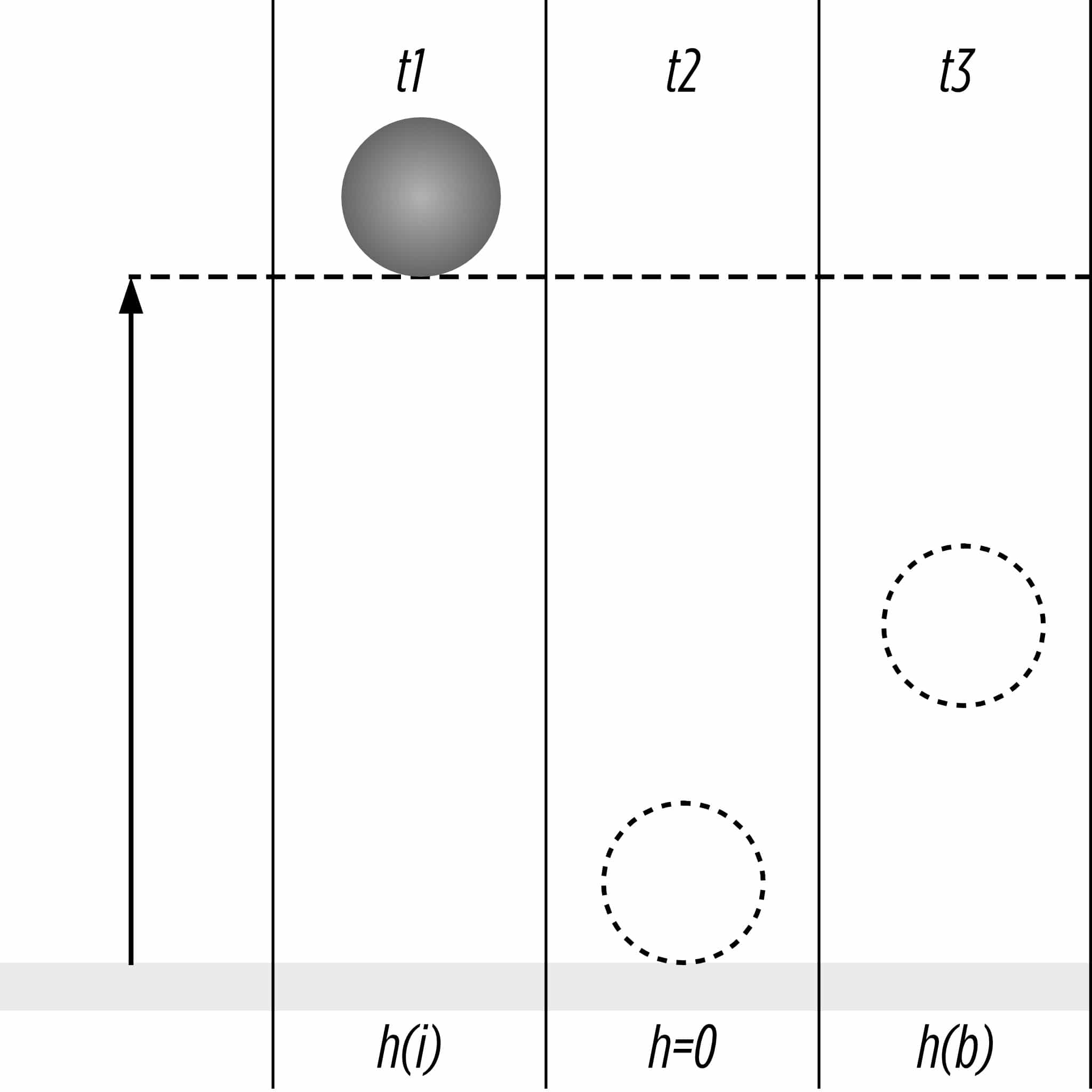

Impact Energy

The requirements for impact-resistant glasses increase significantly from IK class IK07, where the energy gain per level rises by over 100%. This exponential growth in impact resistance demands extremely durable materials and precise integration methods. In high-end classes like IK10 and IK11, the impact energy ranges from 20 to 50 joules, making every detail crucial for performance. Ensuring optimal impact resistance involves carefully integrating the glass into the structure. Our methods are proven and cost-effective, ensuring maximum durability without breaking the bank. We provide reliable solutions to meet these stringent requirements, ensuring your glasses can withstand the toughest conditions.

Impact energy increase IK test

| IK classification | Impact energy (J) | Energy gain (%) |

|---|---|---|

| IK00 | 0.00 | |

| IK01 | 0.14 | |

| IK02 | 0.20 | 42.86 % |

| IK03 | 0.35 | 75.00 % |

| IK04 | 0.50 | 42.86 % |

| IK05 | 0.70 | 40.00 % |

| IK06 | 1.00 | 42.86 % |

| IK07 | 2.00 | 100.00 % |

| IK08 | 5.00 | 150.00 % |

| IK09 | 10.00 | 100.00 % |

| IK10 | 20.00 | 100.00 % |

| IK11 | 50.00 | 150.00 % |

Selecting the right IK code for your product can feel like a daunting task. At Interelectronix, we understand that your decision isn't just about meeting a standard; it's about achieving broader business goals. Do you want to enhance your product's durability or gain a competitive edge? Or perhaps you're looking to extend product lifespan and improve your brand image? Our extensive experience in the industry positions us to help you navigate these choices, ensuring that you get the most out of your investment. In this blog post, we'll explore the key considerations for choosing between IK07 and IK10 and how each option can align with your specific objectives.

IK impact energy increase

What is a joule?

A Joule is a physical unit of energy. In the IK test, you calculate the impact energy by multiplying the height of fall with the weight of the impact element and the number 10.

Impact energy (W) = fall height (h) * weight (m) * 10

Calculation example:

1.00 m drop height * 1.00 kg mass impact element * 10 = 10 joules impact energy

0.50 m drop height * 2.00 kg mass impact element * 10 = 10 joules impact energy

This calculation is not 100% correct, but is a good and fast approximation.

EN 60068-2-75 drop heights

| Energy J | 0,14 | 0,2 | 0,35 | 0,5 | 0,7 | 1 | 2 | 5 | 10 | 20 | 50 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Total mass kg | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | 0,5 | 1,7 | 5 | 5 | 10 |

| Drop height mm ± 1% | 56 | 80 | 140 | 200 | 280 | 400 | 400 | 300 | 200 | 400 | 500 |

Development and services for special glass

We specialize in providing comprehensive glass solutions, offering all the essential services needed for a rapid development cycle and dependable series production. Our expertise covers reliable consulting, developing high-quality glass products, and producing both prototypes and large-scale quantities.

Our services include:

- Conducting qualifying impact tests

- Handling integration development

- Ensuring compatibility with your housing requirements

- Performing cost-benefit analyses

- Testing based on your specifications

- Creating detailed test specifications

- Offering expert advice on materials and technology

- Supplying qualified industrial-grade materials

- Building prototypes and small-scale production runs

With our extensive experience and dedication, we ensure that every step of your glass product development is efficient and meets the highest standards. Whether you need advice, testing, or production, we provide tailored solutions to fit your needs.

Trust us to support you from initial consultation through to the mass production phase.

Why Interelectronix ?

Interelectronix specializes in helping businesses navigate the complexities of choosing the proper IK rating. With our extensive industry experience, we understand your unique challenges and are well-equipped to provide tailored solutions. Whether you want to enhance durability, improve your competitive edge, or showcase your technological capabilities, we can provide the guidance and support you need.

Our team offers comprehensive cost-benefit analyses to help you make informed decisions. We take the time to understand your needs and goals, ensuring you choose the IK rating that best aligns with your objectives. Contact us today to learn more about how we can help you achieve your goals and take your business to the next level.