What materials are used for Optical Bonding?

Optical Bonding and the Difference Between Acrylic and Silicone Bonding Materials

Choosing the right materials for optical bonding is crucial for ensuring long-lasting display performance. While optical bonding significantly improves display readability and durability, the choice of bonding material can greatly impact the display's longevity and visual quality. Acrylic bonding materials, though widely used, have a tendency to yellow over time, affecting the display's clarity. In contrast, silicone bonding materials offer superior longevity and resistance to yellowing. At Interelectronix, we understand the nuances of these materials and can guide you in selecting the best option for your needs.

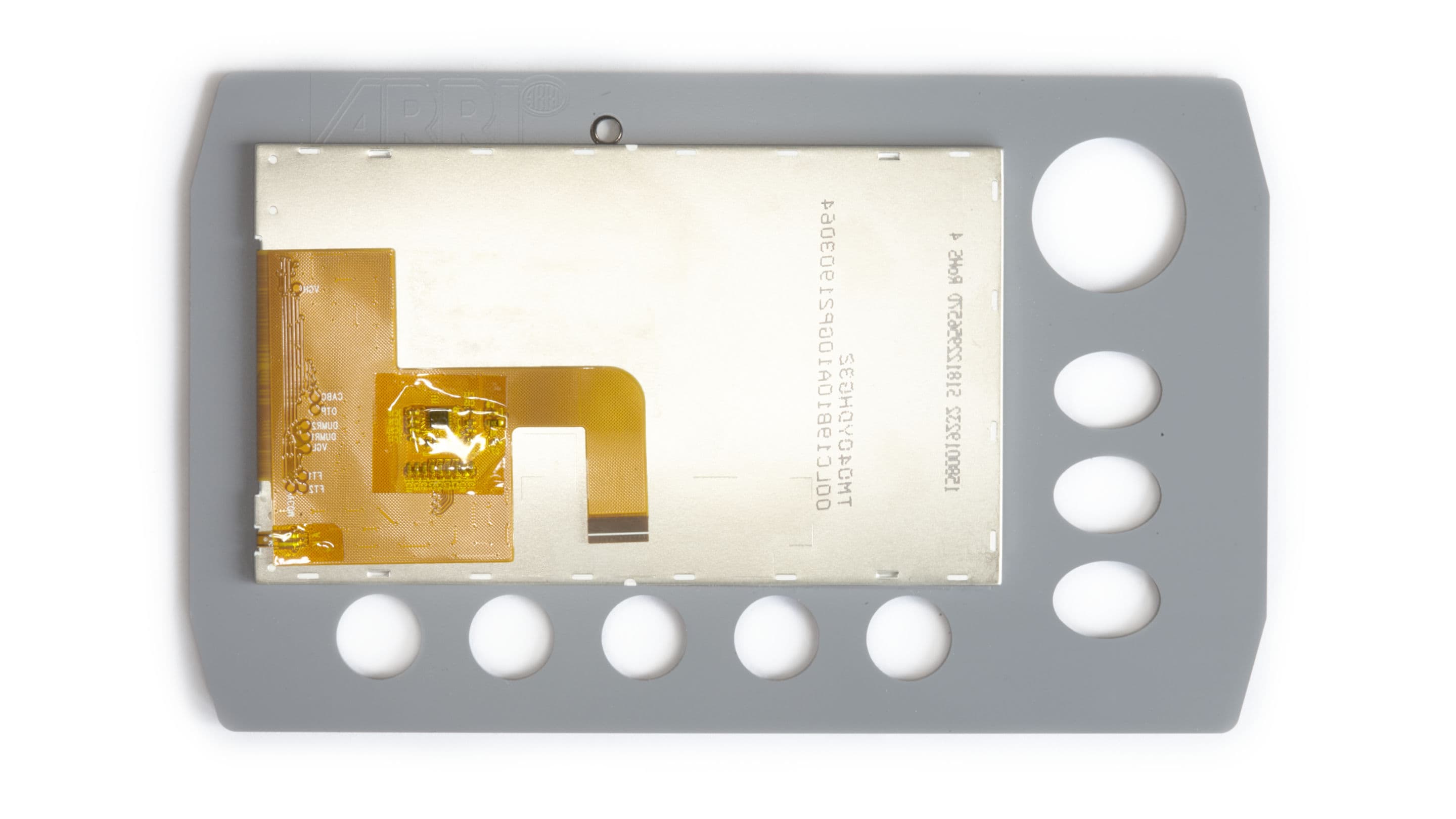

The Basics of Optical Bonding

Optical bonding is a process that involves adhering a transparent adhesive between the display and the cover glass, eliminating air gaps and reducing reflections. This technique enhances the visual performance of displays by improving contrast and readability, especially in bright environments. The choice of adhesive is critical, as it not only affects the initial performance of the display but also its durability over time.

Acrylic Bonding Materials: An Overview

Acrylic adhesives have been commonly used in optical bonding due to their clarity and strong bonding properties. These adhesives provide a robust bond that maintains the integrity of the display under various environmental conditions. However, one significant drawback of acrylic bonding materials is their tendency to yellow over time. This yellowing can degrade the visual quality of the display, making it less effective and aesthetically pleasing.

The Yellowing Effect of Acrylic

The yellowing of acrylic adhesives is primarily caused by exposure to UV light and heat. Over time, these environmental factors break down the chemical structure of the acrylic, leading to discoloration. This yellowing effect not only diminishes the clarity of the display but can also impact the overall user experience. For applications where long-term visual performance is critical, the yellowing of acrylic adhesives can be a major disadvantage.

Silicone Bonding Materials: A Superior Alternative

Silicone adhesives offer a compelling alternative to acrylics, especially in applications where longevity and resistance to yellowing are essential. Silicone bonding materials are known for their excellent clarity, flexibility, and resistance to environmental factors such as UV light and heat. These properties make silicone an ideal choice for optical bonding in demanding environments.

Benefits of Silicone in Optical Bonding

The primary advantage of silicone adhesives is their resistance to yellowing. Unlike acrylics, silicones maintain their clarity over time, even when exposed to harsh conditions. This durability ensures that the display remains clear and effective throughout its lifespan. Additionally, silicone adhesives offer superior flexibility, which helps to absorb shocks and vibrations, further protecting the display.

Application-Specific Considerations

When choosing between acrylic and silicone bonding materials, it's important to consider the specific requirements of your application. For consumer electronics where devices are frequently replaced or upgraded, the initial cost savings of acrylic adhesives might be appealing. However, for industrial, automotive, and medical applications where displays must endure prolonged use and harsh conditions, the long-term benefits of silicone adhesives outweigh the initial investment.

The Economic Impact of Material Choice

While silicone adhesives tend to be more expensive upfront compared to acrylics, their resistance to yellowing and superior durability can result in cost savings over the long term. Reduced maintenance, fewer replacements, and consistent display performance contribute to a lower total cost of ownership. At Interelectronix, we help our clients evaluate these factors to make informed decisions that align with their economic and operational goals.

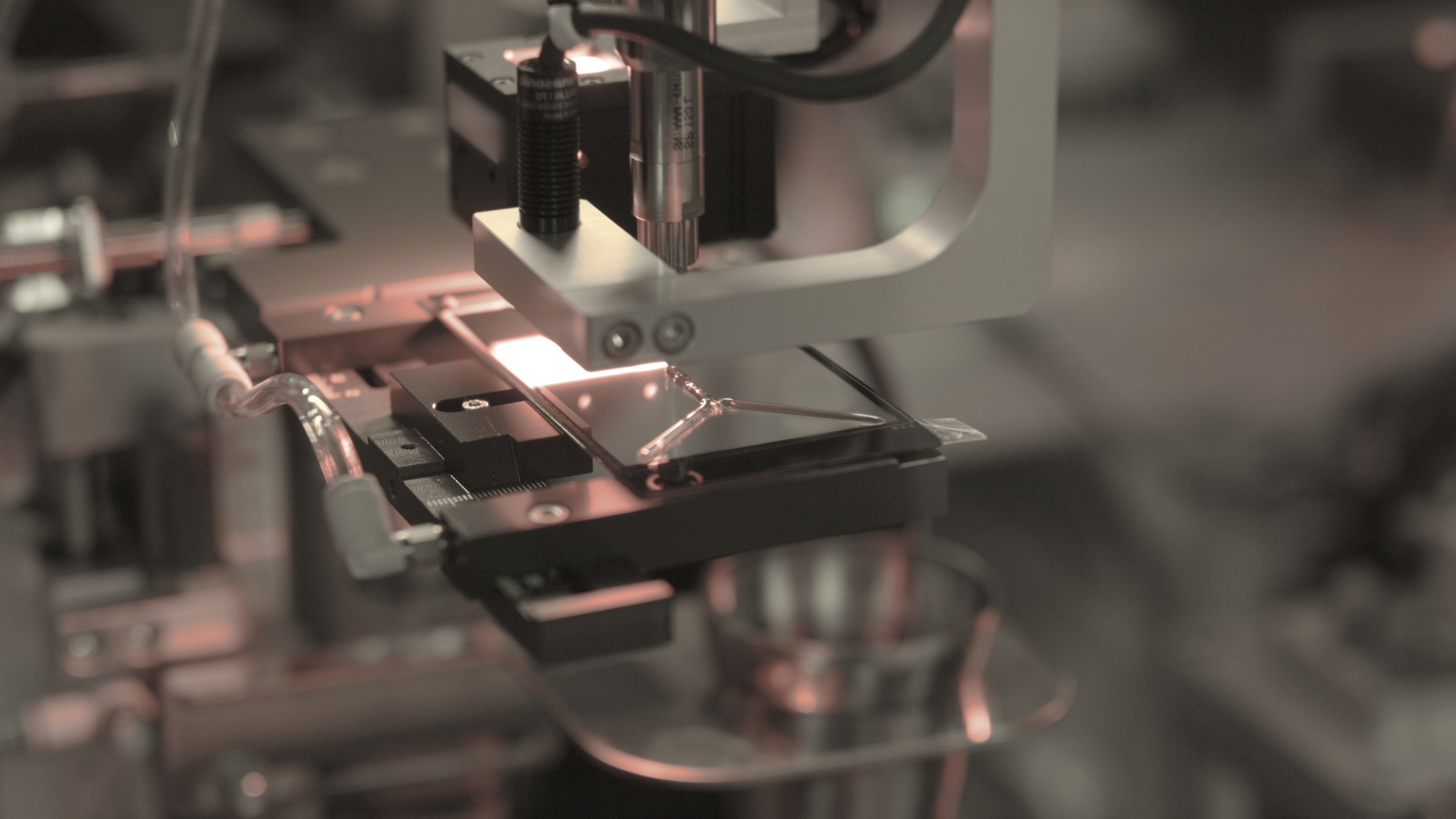

The Role of Expertise in Material Selection

Selecting the right bonding material is not just about understanding the properties of acrylic and silicone. It requires a deep understanding of the application, environmental conditions, and performance expectations. At Interelectronix, we leverage our extensive experience to provide tailored recommendations that ensure the optimal performance of your displays. Our expertise ensures that you choose the bonding material that best meets your specific needs.

Future Trends in Optical Bonding Materials

The field of optical bonding is continuously evolving, with new materials and technologies being developed to address the limitations of existing adhesives. Research into advanced silicones and other innovative materials promises to further enhance the durability and performance of optically bonded displays. Staying informed about these trends and advancements is crucial for businesses looking to maintain a competitive edge in display technology.

Why Interelectronix

Choosing Interelectronix for your optical bonding needs means partnering with a team dedicated to delivering high-quality solutions tailored to your requirements. Our commitment to using the best materials and our deep understanding of optical bonding processes ensure that your displays achieve superior performance and longevity. Contact us today to learn more about how our expertise and cutting-edge materials can enhance your display technology and provide you with a competitive advantage in your industry.