More and more often you can read news from the field of ITO substitutes on the relevant websites. More and more specialized companies are bringing transparent, conductive material onto the market, which is intended to replace the most commonly used ITO (= indium tin oxide) to date.

If you are only a user with touchscreen technology, you may ask yourself what the transparent conductive material is actually used for? And why should there be a replacement for ITO?

ITO as a transparent conductor in smartphones and tablets

If you take a closer look at the touch display of your smartphone or tablet, you will see that it is transparent. But somehow the information at which point you position or move your finger on the display has to be transmitted to the smartphone or tablet.dem tablet. Transparent conductive material shall be responsible for such transmissions. ITO is used for the production of transparent electrodes, which are used, for example, in touch screens.

6 Well-Known ITO Alternatives

In addition to ITO, there are now also other substances of this kind, which are known under the term "transparent conductors". Six of the most well-known ITO substitutes are:

- Metal Mesh

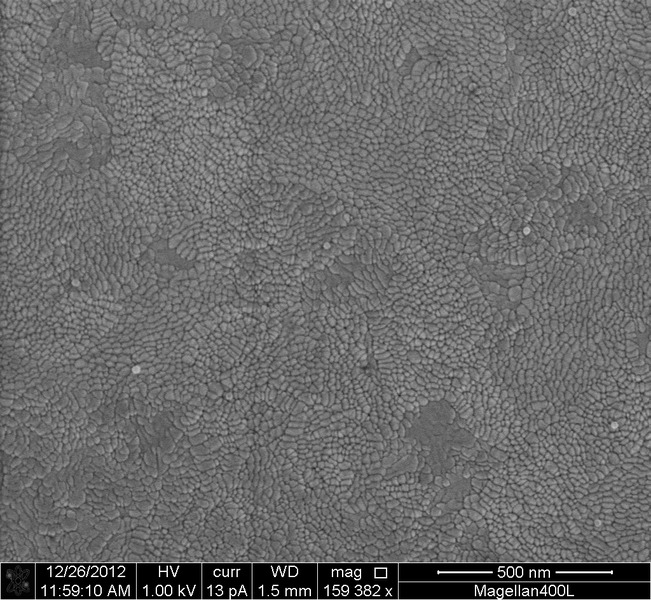

- Silver Nanowires

- Carbon Nanotubes

- Conductive Polymers

- Graphene

- ITO Inks

Comparison: ITO substitute vs. indium tin oxide

{.table-type-a }| ITO Substitute| Advantage over ITO| Special feature|

|----|----|----|

| Metal Mesh| Lower material costs, superior electrical conductivity| Creates moiré patterns (visible lines). Depending on the metal used, oxidation is possible.

| Silver Nanowires| Leader in mass production, Excellent flexibility, high permeability| Difficult to produce silver nanowire ink|

| Carbon Nanotubes| Flexible, better conductivity similar to silver nanowires, stable in areas of high/low humidity or temperature| High material costs as with ITO, Mass production possible, Susceptible to contamination|

| Conductive Polymers| Lower costs in the wet process, flexibility and transparency, | Possibility of combining with other materials|

| Graphene| Excellent flexibility, almost completely transparent| Mass production currently not yet possible|

Reasons to look for a replacement for ITO

The main reason for looking for ITO alternatives is the high price of indium. ITO is relatively expensive. In a somewhat older article in the "New Scientist" magazine, the thesis is even put forward that natural material resources should be exhausted by 2020. Currently, Japan and China are ITO's main suppliers.

Cost-intensive production

Another reason is the cost-intensive manufacturing process. ITO is usually applied to suitable substrates such as glass or plastic sheets under high vacuum.

And last but not least, the final material is brittle and inflexible, which causes problems when dealing with flexible substrates.

More and more companies are introducing ITO substitutes, which are mainly used in electronic products for end users due to the more cost-effective production. Because of new, more superior, transparent conductive materials, the PCAP market is in a state of upheaval. ITO will be replaced by lighter, more flexible films with improved optical quality and lower production costs.

This makes devices such as tablets, ultrabooks, smartphones and the like thinner, lighter and also more responsive than before and enables new technological advances for the touchscreen industry.