Wearable electronic devices (wearables) are becoming more and more popular, so we won't tell you anything new. There are now more and more touchscreen manufacturers who use new manufacturing processes to produce flexible touch surfaces. The brittle and less flexible glass surface has become obsolete, especially in consumer applications.

Mobility and durability

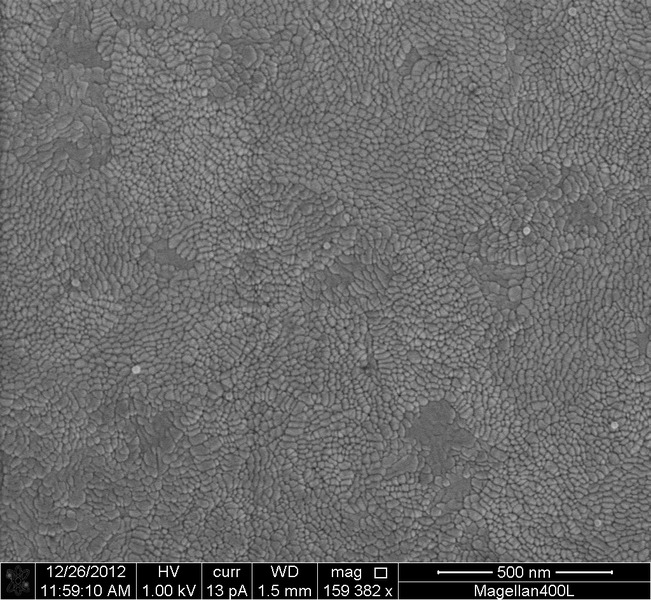

In the meantime, many touchscreen applications are based on the new silver nanowire-based touch surface. Due to the improved mobility and service life, as well as unlimited design freedom, this will probably soon completely replace the currently leading heavyweight of the industry - ITO. Touchscreens of tablets, laptops and smartphones are getting thinner and thinner. The demand for curved and aesthetically pleasing touch displays is also increasing in the public sector.

ITO versus silver nanowires

Compared to indium tin oxide (ITO), several factors speak in favor of the use of silver nanowires (SNW). The new Touchs products with this material are lighter, thinner, responsive and, above all, more cost-effective to produce. In addition, they provide excellent flexibility, as well as high light transmission. Since, depending on the manufacturing process, hardly any or no chemicals are used that have to be disposed of at great expense, a more environmentally friendly production process is also possible than with ITO materials.

If you would like to learn more about the design of a touchscreen to see where ITO is used, more information about the touchscreen design is available on our website.