In the fast-paced world of industrial technology, it's not just about having the latest hardware—it's about ensuring that hardware can withstand the toughest conditions. At Interelectronix, we understand the critical need for robust, reliable electronics that perform under pressure. You’ve invested in high-quality ARM baseboards for your systems on modules, and it’s our mission to protect that investment. With our extensive experience in conformal coatings, we ensure your technology not only survives but thrives in harsh environments. Let's delve into how these coatings make all the difference and why partnering with Interelectronix is your best move.

The Importance of Protecting ARM Baseboards

ARM baseboards, when integrated with systems on modules (SoMs), are the backbone of countless industrial applications. These systems power everything from manufacturing robots to remote sensors in oil fields. However, these environments can be harsh—exposing electronics to dust, moisture, chemicals, and extreme temperatures. Without adequate protection, even the most advanced ARM baseboards can fail, leading to costly downtime and repairs. This is where conformal coatings come into play, acting as a shield to safeguard sensitive electronics from external threats.

Understanding Conformal Coatings

Conformal coatings are thin layers of protective material applied to electronic circuits. These coatings conform to the contours of the board, providing a barrier against contaminants and environmental stressors. There are various types of conformal coatings, including acrylics, silicones, polyurethanes, and epoxies, each offering distinct advantages depending on the specific application. Choosing the right type of coating is crucial for ensuring the longevity and reliability of ARM baseboards in challenging environments.

Why Conformal Coatings are Essential

The environments in which ARM baseboards operate can be unpredictable and unforgiving. Dust and dirt can cause short circuits, moisture can lead to corrosion, and chemical exposure can degrade materials. Conformal coatings provide a crucial layer of defense, preventing these issues from affecting the performance of the electronics. By protecting the circuitry, conformal coatings help maintain the integrity and functionality of the baseboards, reducing the risk of failure and extending the lifespan of the devices.

Types of Conformal Coatings and Their Benefits

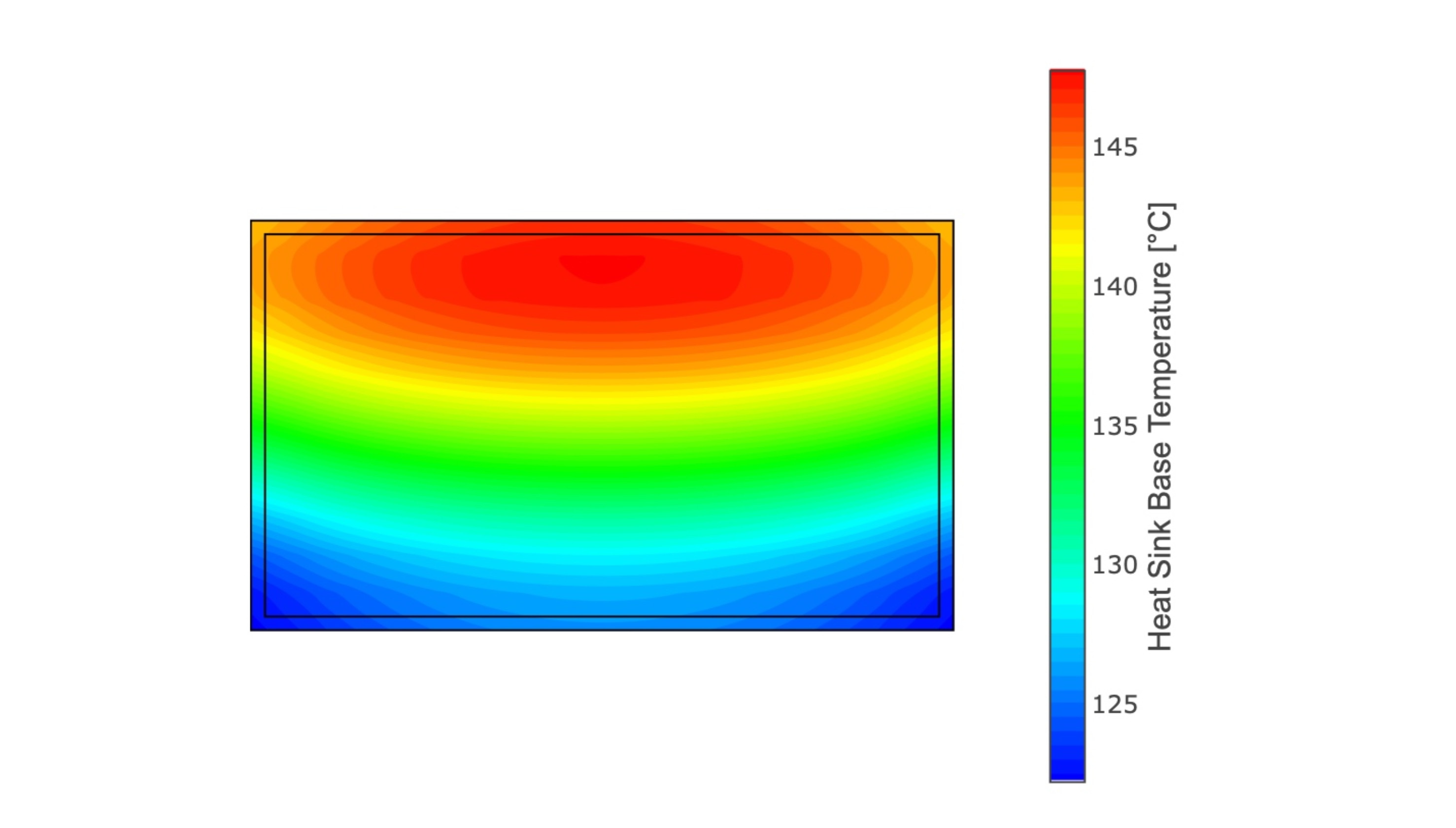

Selecting the appropriate conformal coating for ARM baseboards depends on the specific environmental challenges the equipment will face. Acrylic coatings are popular for their ease of application and reworkability, making them ideal for less severe conditions. Silicone coatings offer excellent thermal stability and flexibility, perfect for high-temperature environments. Polyurethane coatings provide robust chemical resistance, while epoxy coatings are known for their mechanical strength. Each type of coating offers unique benefits, and understanding these can help in making the right choice for your application.

Application Techniques and Best Practices

Applying conformal coatings to ARM baseboards is a precise process that requires attention to detail. Techniques include dipping, spraying, and brushing, each suitable for different production volumes and board designs. Ensuring even coverage without compromising the functionality of connectors and components is critical. At Interelectronix, we follow industry best practices to ensure optimal coating performance. Our experienced technicians use state-of-the-art equipment to apply coatings meticulously, guaranteeing consistent protection across all areas of the board.

Testing and Quality Assurance

Quality assurance is paramount when it comes to conformal coatings. At Interelectronix, we employ rigorous testing methods to verify the effectiveness of our coatings. This includes environmental testing to simulate real-world conditions, adhesion tests to ensure the coating stays in place, and electrical testing to confirm that the coating does not interfere with the board’s performance. Our comprehensive quality assurance process ensures that every coated ARM baseboard meets the highest standards of reliability and durability.

Custom Solutions for Unique Challenges

Every industrial application has its own set of challenges, and a one-size-fits-all approach rarely works. At Interelectronix, we offer customized conformal coating solutions tailored to the specific needs of our clients. Whether you’re dealing with extreme temperatures, high humidity, or exposure to corrosive chemicals, we can develop a coating strategy that provides optimal protection. Our team of experts works closely with clients to understand their requirements and deliver solutions that enhance the performance and longevity of their ARM baseboards.

The Role of Conformal Coatings in Compliance and Standards

In many industries, compliance with standards and regulations is not optional—it’s a necessity. Conformal coatings play a significant role in meeting these requirements. Standards such as IPC-CC-830 and MIL-I-46058C outline the criteria for the performance and reliability of conformal coatings. At Interelectronix, we ensure that our coatings meet or exceed these standards, providing our clients with the assurance that their products comply with industry regulations. This commitment to quality and compliance helps our clients avoid penalties and maintain their reputation for reliability.

The Future of Conformal Coatings

The technology behind conformal coatings is constantly evolving, driven by the need for improved performance and new environmental challenges. Advances in materials science are leading to the development of coatings with enhanced properties, such as greater flexibility, higher thermal resistance, and better environmental protection. At Interelectronix, we stay at the forefront of these developments, continually updating our processes and materials to offer the latest and most effective solutions. By partnering with us, you gain access to cutting-edge technology that keeps your ARM baseboards protected in the most demanding conditions.

Partnering with Interelectronix for Reliable Protection

In the demanding world of industrial electronics, ensuring the reliability and longevity of your ARM baseboards is crucial. Conformal coatings provide the necessary protection to keep your systems running smoothly, even in the harshest environments. At Interelectronix, we combine our expertise in conformal coatings with a deep understanding of industrial applications to deliver tailored solutions that meet your specific needs. We invite you to explore the benefits of our protective coatings and see how we can help safeguard your investment. Contact us today to learn more about our services and how we can support your operations.