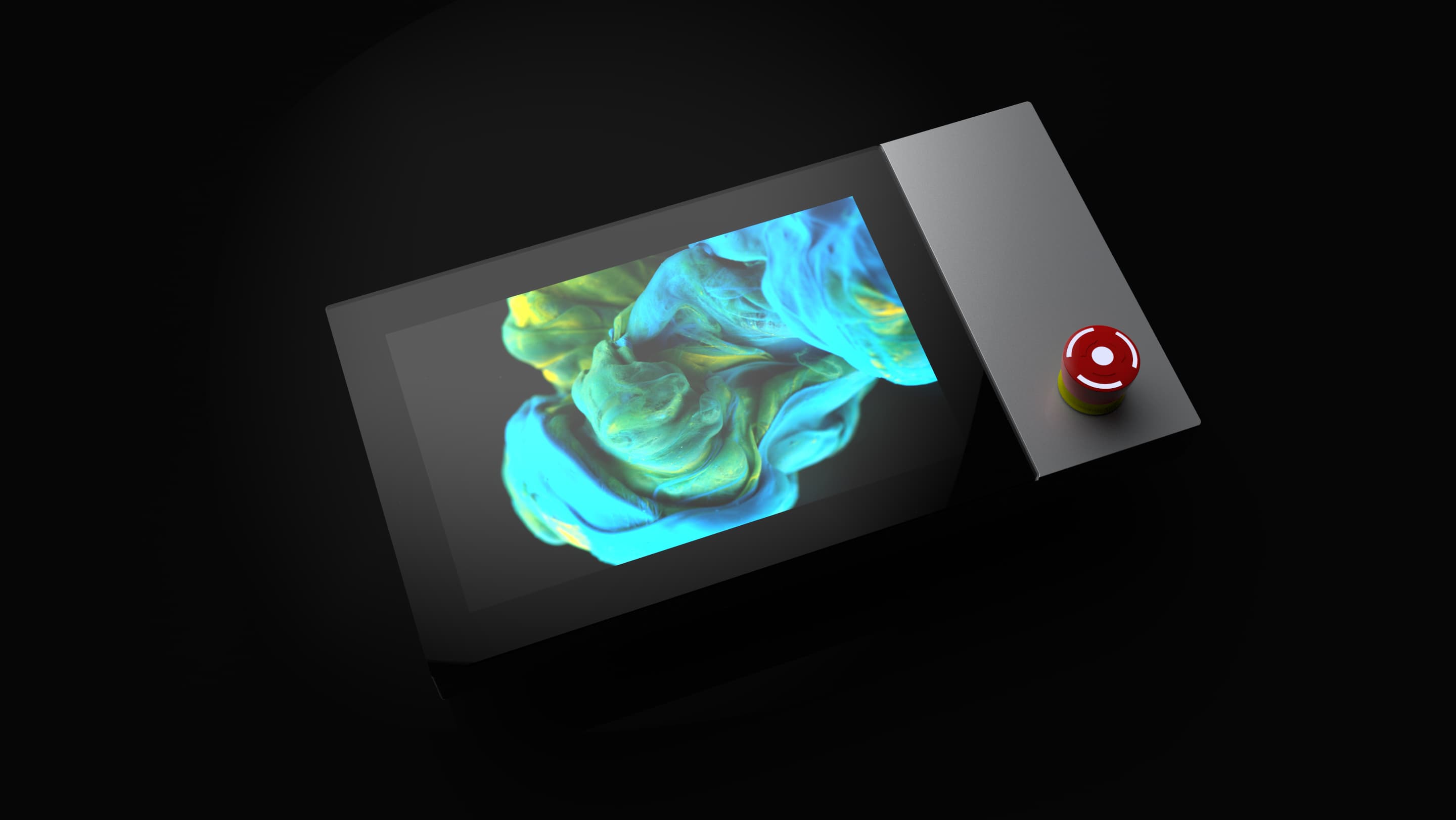

Smart manufacturing is transforming industries with the integration of advanced technologies that enhance efficiency, productivity, and adaptability. Among these technologies, Human-Machine Interfaces (HMIs) play a crucial role by enabling seamless interaction between operators and complex industrial systems. In recent years, touch screen HMIs have undergone significant innovations, revolutionizing the way humans interact with machines in manufacturing environments. This blog post explores the latest advancements in touch screen HMIs for smart manufacturing, highlighting their impact on the industry.

Evolution of Touch Screen HMI

Touch screen HMIs have come a long way since their inception. Initially, they were simple interfaces with limited functionality, primarily used for basic control and monitoring tasks. However, advancements in touch screen technology, coupled with the rise of smart manufacturing, have driven the development of more sophisticated and versatile HMIs.

Early HMIs: From Buttons to Touch Screens

In the early days, HMIs relied heavily on physical buttons and switches for user input. These interfaces were often cumbersome and prone to wear and tear. The introduction of touch screen technology marked a significant milestone, replacing physical buttons with a more intuitive and flexible interface. Early touch screens used resistive technology, which required pressure to register input. While this was a significant improvement, it had limitations in terms of multi-touch capability and durability.

Capacitive Touch Screens: A New Era

The shift from resistive to capacitive touch screens brought about a new era in HMI design. Capacitive touch screens detect touch through the electrical properties of the human body, allowing for more precise and responsive interactions. This technology supports multi-touch gestures, enabling operators to perform complex tasks with ease. Moreover, capacitive touch screens are more durable and can withstand harsh industrial environments, making them ideal for smart manufacturing applications.

Key Innovations in Touch Screen HMI

The rapid advancements in touch screen technology have paved the way for several key innovations in HMI design. These innovations enhance user experience, improve operational efficiency, and ensure greater reliability in manufacturing environments.

Multi-Touch and Gesture Control

Modern touch screen HMIs support multi-touch and gesture control, allowing operators to use multiple fingers simultaneously to interact with the interface. This capability is particularly useful for complex tasks that require zooming, rotating, and swiping gestures. Multi-touch technology improves the intuitiveness and efficiency of HMIs, reducing the learning curve for operators and increasing productivity.

Enhanced Durability and Ruggedness

Smart manufacturing environments are often harsh, with exposure to dust, moisture, extreme temperatures, and vibrations. To address these challenges, touch screen HMIs have been engineered to be more durable and rugged. Innovations such as chemically strengthened glass, water-resistant coatings, and robust enclosures ensure that touch screens can withstand the rigors of industrial use. This enhanced durability extends the lifespan of HMIs and minimizes downtime due to equipment failure.

Advanced Haptic Feedback

Haptic feedback technology has been integrated into modern touch screen HMIs to provide tactile sensations in response to touch interactions. This feedback enhances the user experience by simulating the feel of physical buttons and switches, making the interface more intuitive. Haptic feedback can also improve accuracy by providing immediate confirmation of inputs, reducing the likelihood of errors in critical operations.

High-Resolution Displays

High-resolution displays are another significant innovation in touch screen HMIs. These displays offer superior clarity and sharpness, enabling operators to view detailed information and complex graphics with ease. High-resolution screens enhance the visibility of data, improve situational awareness, and allow for more effective monitoring and control of manufacturing processes. Additionally, advancements in display technology, such as OLED and IPS panels, provide wider viewing angles and better color reproduction.

Integration with IoT and Data Analytics

The integration of touch screen HMIs with the Internet of Things (IoT) and data analytics platforms is revolutionizing smart manufacturing. Modern HMIs can connect to a wide range of sensors, devices, and systems, collecting real-time data from the manufacturing floor. This data can be analyzed and visualized directly on the HMI, providing operators with actionable insights and predictive analytics. The seamless integration with IoT enables smarter decision-making, proactive maintenance, and optimization of production processes.

Customizable and Adaptive Interfaces

Customizability and adaptability are crucial features of modern touch screen HMIs. Operators can customize the interface to suit their specific needs and preferences, creating a personalized user experience. Adaptive interfaces can also change dynamically based on the context of use, displaying relevant information and controls based on the current task or process stage. This flexibility enhances usability and ensures that operators have access to the right information at the right time.

Enhanced Security Features

As manufacturing systems become more interconnected, the security of touch screen HMIs has become a top priority. Innovative security features, such as biometric authentication, encrypted communication, and role-based access control, have been integrated into HMIs to protect against unauthorized access and cyber threats. These security measures ensure that sensitive data and critical operations are safeguarded, maintaining the integrity and reliability of manufacturing processes.

Impact of Innovations on Smart Manufacturing

The innovations in touch screen HMI technology are having a profound impact on smart manufacturing, driving significant improvements in efficiency, productivity, and overall operational performance.

Improved Operator Efficiency

The intuitive and user-friendly nature of modern touch screen HMIs reduces the time and effort required for operators to interact with industrial systems. Features such as multi-touch gestures, high-resolution displays, and haptic feedback streamline workflows and minimize errors. As a result, operators can perform tasks more efficiently, leading to increased productivity and reduced operational costs.

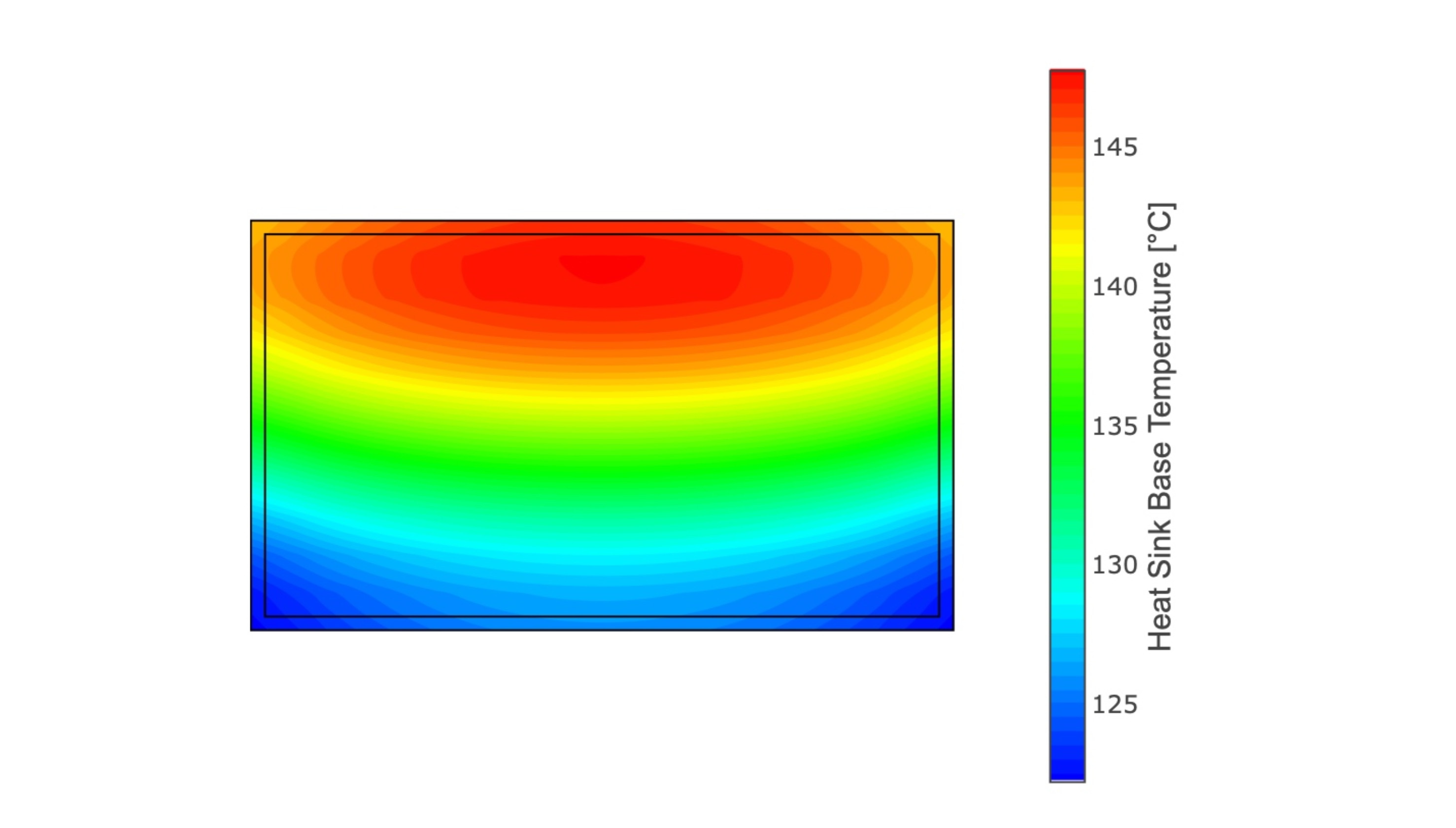

Enhanced Monitoring and Control

High-resolution displays and advanced data visualization capabilities enable operators to monitor complex processes in real-time with greater clarity and accuracy. The integration with IoT and data analytics platforms provides valuable insights into system performance, allowing for proactive maintenance and optimization. Enhanced monitoring and control capabilities contribute to improved process reliability, reduced downtime, and higher product quality.

Increased Flexibility and Adaptability

The customizability and adaptability of modern touch screen HMIs provide greater flexibility in manufacturing operations. Operators can tailor the interface to their specific needs, ensuring that they have the most relevant information and controls at their fingertips. Adaptive interfaces that change based on context enhance usability and efficiency, allowing for seamless adjustments to changing production requirements and conditions.

Enhanced Safety and Security

Innovative security features integrated into touch screen HMIs help protect against cyber threats and unauthorized access. Biometric authentication, encrypted communication, and role-based access control ensure that only authorized personnel can access critical systems and data. These security measures enhance the safety and integrity of manufacturing operations, reducing the risk of disruptions and data breaches.

Facilitated Training and Skill Development

The intuitive design and user-friendly nature of modern touch screen HMIs simplify the training process for new operators. The use of multi-touch gestures, haptic feedback, and high-resolution displays creates a more engaging and interactive learning experience. This facilitates faster skill development and reduces the time required for operators to become proficient in using the HMI, ultimately improving workforce productivity and efficiency.

Future Trends in Touch Screen HMI for Smart Manufacturing

The future of touch screen HMI technology in smart manufacturing looks promising, with several emerging trends poised to further revolutionize the industry.

Augmented Reality (AR) Integration

Augmented Reality (AR) is set to play a significant role in the future of touch screen HMIs. AR can overlay digital information onto the physical world, providing operators with real-time data and insights directly within their field of view. This integration can enhance situational awareness, improve decision-making, and facilitate complex maintenance and repair tasks.

Artificial Intelligence (AI) and Machine Learning

The integration of Artificial Intelligence (AI) and Machine Learning into touch screen HMIs holds immense potential for smart manufacturing. AI-powered HMIs can analyze vast amounts of data, identify patterns, and provide predictive insights. Machine learning algorithms can continuously learn and adapt, optimizing HMI functionality and improving operational efficiency over time.

Voice and Gesture Recognition

Voice and gesture recognition technologies are expected to complement touch screen interactions, providing alternative input methods for operators. Voice commands can enable hands-free operation, while gesture recognition can enhance the intuitiveness and flexibility of the HMI. These technologies can further streamline workflows and improve the overall user experience.

Advanced Connectivity and Edge Computing

The adoption of advanced connectivity solutions, such as 5G, and the implementation of edge computing are set to enhance the capabilities of touch screen HMIs. These technologies enable faster data processing, reduced latency, and real-time decision-making. Advanced connectivity and edge computing will further integrate touch screen HMIs with the broader smart manufacturing ecosystem, driving greater efficiency and responsiveness.

Conclusion

The innovations in touch screen HMI technology are transforming smart manufacturing by enhancing user experience, improving operational efficiency, and ensuring greater reliability. From multi-touch and gesture control to high-resolution displays and IoT integration, these advancements are driving significant improvements in the way operators interact with industrial systems. As the industry continues to evolve, future trends such as AR integration, AI, and advanced connectivity will further revolutionize touch screen HMIs, paving the way for a smarter, more efficient, and adaptable manufacturing landscape. The continued development and adoption of these technologies will play a crucial role in shaping the future of smart manufacturing, driving growth and innovation across the industry.